How to Replace Carpet Quad Cab 2003-08 Dodge Ram 1500

Created on: 2016-06-06

Check out this video to learn how to replace the carpet in your 03-08 quad cab Dodge Ram 1500.

-

step 1 :Disconnecting the Battery

- Disconnect the negative terminal with a 10mm wrench

- Let the vehicle sit for 30 minutes to let the airbag modules power down

-

step 2 :Removing the Seats

- Undo the two 15mm bolts at the front of the seat brackets

- Remove the two 15mm bolts at the back of the rail

- Spray the underside of the vehicle where the bolts are with rust penetrant if needed

- Remove the seat belt cover

- Remove the T45 Torx bolt from the seatbelt

- Pull the seat back and buckle in the seat with the rear seat belt

- Disconnect the electrical connector under the driver's seat

- Disconnect the red safety tab from the wiring harness

- Remove the four 13mm nuts holding the seat together

- Remove the center seat

- Remove the driver and passenger seats

-

step 3 :Removing the Carpet

- Unscrew the thumb screw from the floor

- Remove the jack from the vehicle

- Remove the emergency roadside kid

- Remove the T30 screws from the floor

- Pull the kick panels up and out

- Pull out the trim under the cup holder

- Fold up the rear seat by pulling up on the bottom

- Pull the snap out and fold the chair seat up

- Remove the snap with a T20 Torx socket

- Pull out the plastic clips holding the carpet underneath the seats

- Remove the rear kick panel sills

- Pull the carpet out from the sills

- Pop out the rear cup holder

- Pull the carpet out from the center console and driving pedals

- Pull the wiring harness through the carpet

- Bring the carpet out of the door

-

step 4 :Preparing the New Carpet

- Lay the new carpet over the old one

- Pad the carpet to the shape of the old one and let it sit for a few hours

- Trace an outline of the original carpet along the excess of the new carpet

-

step 5 :Installing the Carpet

- Line up the carpet with the interior shapes that protrude out

- Press the carpet into the interior trim

- Trim off any excess that covers the trim mounting points

- For parts like the back seats, simply make a slit with a utility knife

- Cut out a cross and create a small oval so the cup holder retains the carpet

- Press the cup holder into place

- If you have an occupant classification system, be very careful not the cut a wire

- Carefully find the edge of the module

- Cut around the module

- Fit the carpet nice and tight around the edges of the rear kick panel

- Snap the kick panel trim into place

- Trim the carpet along where the front kick panel will place near the pedal

- Make sure the carpet isn't interfering with any wires/e-brake, etc near the pedal cluster

- Press the kick panel into place

- Trim along the center console and passenger side

- Press the passenger kick panel into place

- Press the center panel trim into place

- Feel around for the seat bracket holes and create a hole with a center punch

- Punch out any alignment holes atop the bracket

- Cut a flap along the back for the wiring harness

- Pull the power-heated seat wiring harness through

- Measure from the alignment pinhole from the top of the rail to the rear bracket hole

- Locate and punch out the remaining three holes with the measurement

- Punch holes for the rear seat clips

- Punch a hole for the bungee mounting point

- Tighten the T20 snap into place

- Clip the rear seat carpet into place

- Lower the rear seats into place

- Clip the rear seat into place

- Find the three emergency jack and tool kit holes

- Punch a hole through

- Screw the spare tire jack into place

- Tighten the spare tire tools and T30 Torx screws

- Vacuum out the carpet

-

step 6 :Installing the Seats

- Insert the seats into place

- Leave them laid back

- Tighten the 13mm bolts the center console onto the passenger seat

- Clip the wiring harness into place

- Connect the wiring harness

- Lay the seats back down and align the bolt holes up

- Tighten the 15mm bolts to the front of the seat

- Tighten the 15mm bolts to the back of the seat

- Torque the seat bolts to 30 foot-pounds

- Insert the seatbelt tab into place

- Tighten the T45 bolt into the seat belt

- Torque the bolt to 29 foot-pounds

- Press in the seatbelt cover

-

step 7 :Connecting the Battery

- Tighten the 10mm negative battery terminal

Tools needed

-

13mm Socket

Socket Extensions

Torque Wrench

Hammer

15mm Socket

Rust Penetrant

18mm Socket

Utility Knife

Measuring Tape

T20 Driver

Center Punch

T45 Socket

10mm Socket

Ratchet

Needle nose pliers

Marker / Writing Utensil

Brought to you by 1AAuto.com, your source for quality replacement parts and the best service on the Internet.

Hi, I'm Mike from 1A Auto. I hope this how-to video helps you out, and next time you need parts for your vehicle, think of 1AAuto.com. Thanks.

In this video, we're going to show you how to install a carpet in this Dodge Ram. This is a 2008 quad cab 1500. The procedure is the same for any 2003-2008 quad cab 1500. Items you'll need are a new carpet from 1AAuto.com, 10-18mm sockets with ratchet and extensions, T20-45 Torx bits, pliers, penetrating oil, a marker, a utility knife, hammer and center punch, a tape measure, and a torque wrench.

Before working on any part of the electrical system, you'll want to use a 10mm wrench to remove the negative terminal of your battery and set it off to the side.

After the battery's been disconnected and the vehicle's sat for 30 minutes to allow the airbag modules to power down, you'll need a 15mm socket to undo two 15mm bolts at the front of the seat brackets. Remove the two 18mm bolts at the back of the rail. You may want to spray the underside of the vehicle where the bolts go through with some penetrating oil.

Remove the cover at the bottom of the seat belt by snapping it out. Undo the T45 Torx bolt, holding the bottom of the seat belt down. Repeat these steps on the opposite side.

Lay the seats back. Secure the rear seat belt around the head rest. Buckle it in so you can work on the bottom side of the seats. Disconnect the electrical connector under the driver's seat. Disconnect the two electrical connectors on the passenger's side of the center seat. Pull back on the red safety tab on the rearmost connector so you can push down and release it.

Remove the wire loom retainer from the front driver's corner of the harness. Remove the connectors from the base of the seats by prying them out carefully with a trim plier or a pair of needle nose. Remove the four 13 millimeter nuts holding the seats together.

Remove the seat belt that was securing the seats. Lay them down. Make sure that your seat belts aren't tangled together. Remove the center seat from the vehicle. Carefully remove the driver and passenger seats from the vehicle. You may need a friend to help you if you can't maneuver them out on your own without damaging the truck.

To remove the jack that was under the passenger's seat, unscrew the thumb screw from the floor. You don't have to use pliers to remove this, but it can certainly make it easier when they're being stubborn. Just be sure not to clamp down too tight where you risk breaking the plastic. Remove the jack from the vehicle.

Our vehicle is missing the emergency road-side service kit, but the screws are still there, so we'll use a T-30 Torx bit to remove them. Remove the kick panels on both sides by pulling up and back. Remove the trim under the cup holder by popping it out from both sides. Fold up your rear seats by simply pulling up on the bottom.

This tray is designed to lay out for more space in the back. It has a snap over here. Undo the snap. Fold that up too. You're going to use a T20 Torx socket to remove the snap on the carpet. We'll just snap that back into the seat so we don't lose it. Repeat these steps on the opposite side.

Inside the storage compartment and under the seat are a bunch of plastic seats that hold the carpet in. Reach under and remove those. Be sure to pull on them evenly. Sometimes they may just pull through the carpet. That's all right. Just make sure you remove them so you have them to snap into the new piece. Remove the rear kick panel sills just like the front. Pull up on them. You don't have to remove them fully. Just get the rear clips so the back of the carpet can be released. Pry it up from under the B pillar trim. Repeat these steps on the opposite side. Pop out your rear cup holder. Untuck your carpet from the center console and from under the pedals. Repeat this step on the opposite side. Pull the wiring harness through the carpet. Fold it up and rotate it. Bring it out the door.

Here we have our old carpet out of the car and our new carpet from 1A Auto. You see it comes out of the box roughly the same size. You can see it's a little bit darker because it's a nice and freshly dyed, brand new clean carpet. The shapes are all pre-pressed in, but they do have to rest after they've come out of the box, so you're going to lay your new carpet over your old carpet, as square as you can with your old carpet.

Lay it underneath your new carpet. Pat it into the same shape. You can see our creases for the back are starting to pop out now. With everything patted into the shape of the old carpet, allow it to rest for a few hours to let everything sink in to a more factory shape. We'll still have to trim and cut some holes to fit up with all our factory locations and trim the edges, where every truck's different. It does come a little bit over-sized. We'll show you how to do that after it's taken shape.

After you've allowed your new carpet to rest for a few hours and retake the shape of the original piece, get it fitted as tight as you can to the old piece, and we'll take a paint pen or some other type of marker. Just trace a rough outline of our original carpet. It's usually better to go a little bit big here. We can finish cut once our carpet's in the vehicle.

Use the utility knife to rough cut the shape and size of the carpet before installing into the vehicle. Reinstall your carpet into the vehicle.

You want to start by lining up any identifying shapes or markers. In this case, where the carpet rolls in under the back seat is a pretty easy shape to follow, so we'll start there. We'll start tucking our carpet back under the trim, under our pedals, and up under the center console. Don't be afraid if everything's not lining up perfectly; we can always trim to fit.

Here we have a good example of where you may have to re-trim the carpet inside the car. These mounting points for our trim panel are covered by the carpet. We're going to lay it in, trim that back a little, and you can see up here we're covering this mounting point as well. We're going to trim that back a little more. Once we have our corners fitted in nicely, we'll start finding some mounting holes, making a slit so we can install our plastic retainers.

Now we have an issue fitting over this corner here. Trim that out and get that wrapped around nice. Now we can go in and trim out all this excess carpet below our mounting points and try to keep a nice straight line there to make it look nice. Got to feel for the divot here.

Go right in the middle out to each side, front, and rear with the carpet. Going to trim it close, not too close so our cup holder actually retains the carpet a little bit.

Reinstall your cup holder, snapping it into place. I've removed my boots because we have a nice new carpet in the vehicle, and you're going to be crawling around in here a lot. Just want to watch out for it and make sure you don't go tracking any mud or dirt and stain the new carpet that you just put in. Right here, you can feel the occupant classification system if your vehicle's equipped. That comes right out of the carpet in the factory unit.

You have to be very careful not to cut a wire here. There is a plastic cover on the top, so we're going to put a little notch in it. Lift up our carpet, put that cut the rest of the way through until we find the edge of our module, at which point we'll cut around it.

Again, lift up the carpet as much as you can here when you're cutting just to make sure that you don't accidentally cut any wires on this module, especially or anything else hidden under the carpet. Once you've found the module, go ahead and press the carpet down around it.

You can see, as we're fitting our carpet here, you want to bring it back nice and tight to the edges. You could see we have a lot of carpet bunching up over in this corner. We're going to pop our trim panel back up. We can trim out this whole corner here and make it fit that much nicer. Less is going to be more in a situation like this. We can always pull it out and trim some more carpet back, but if you go too far and it doesn't tuck underneath, then that's just going to be how it is.

Snap it back into place. You have a nice tight-fitting edge. Again, we need to do some more trimming over on the edge here, so we're going to fit all of our edges in as tight as we can here. We're pretty good under the B pillar, but when we get over to our kick panel here, we got a lot of slack, and again, we're just going to trim a little at a time. Don't worry too much about these ridges of the seat mounts. When we bolt the seats in, these will take their shape a lot nicer.

Getting up under the pedals, this isn't too particular. It's really a matter of how much you want to cut and cover. There's no reason not to leave it a little bit long and really allow the carpet to stretch and settle in right. We don't want to cover or interfere with where our trim's going to go here, so we'll keep it pretty low to the floor and still leave a little bit to tuck up underneath.

Again, always checking for wires. The last thing you want to do is install your carpet and then find out some interior part doesn't work because you nicked a harness somewhere and pull it all back out. This up here could interfere with the e-brake mechanism, so we'll trim that back some.

The rest of our carpet under the pedal cluster looks nice. We're going to interfere here. Trim it down, make that edge fold in nice and clean.

We'll reinstall our kick panel now. It pops in at the front and then down below. We have a little bit of trimming we can do here—the rest we can tuck away. We'll reinstall our passenger kick panel and then our center panel.

We took a look at our old carpet for a reference to find the mounting holes. Feel around for them. Once you've found them, you can use a sharp center punch. Make sure you're where you want to be. Then we'll just open that hole up a little bit bigger and make sure our bolts go in easily.

Once we've got our cut-out for our seat bracket, we'll take one of the front seat bolts. Just put in a few threads to help keep our alignment. We'll repeat these steps to find the rest of the mounting holes. Directly above the bolt on the inside of both front brackets at the top is an alignment hole you'll want to punch out as well.

Right in the center at the back of the carpet, you're also going to want to cut out. You want to cut a little flap to allow the wire harness to come through. There's nothing on the passenger's side of our vehicle, but on the driver's side, we'll have to pull through the harness for the power and heated seats.

For reference, measuring from the alignment pinhole in the top of the rail that the front of the seat bolts to, it's approximately 19-1/2 inches back to the rear hole. Using this measurement, locate and punch out the remaining three bolt holes. To find the holes for the bungees, remove three of the plastic retainers. Fold back the inner carpet. Reinstall the middle retainer.

Locate the hole, the bungee mounting point, and punch through on the other side. Reinstall the button. Remove your plastic retainer. Put your inner carpet back in place. Snap your retainers back in. Tuck in any carpet that may have been disturbed in the process. Double-check that your hold-down is secure.

Repeat these steps on the opposite side. Locate the three holes under the passenger's seat for the emergency jack and tool kit. Again, you'll just have to compare to the old carpet.

Feel around for the hole. Screw your spare tire jack back down to the floor. If you have your spare tire tools, reinstall those. We just have the screws, so we're going to reinstall them with a T30 Torx bit.

We've installed all of our seat-mounting hardware hand-tight just to ensure that everything lines up the way we want it to. If yours doesn't, make some last-minute adjustments, and then we're going to clean the carpet before we reinstall our front seats.

Reinstall your seats. Remember to leave them laid back so we can connect them all together. Reinstall the center console onto the passenger seat. Tighten them down with the 13 millimeter socket and ratchet.

Reinstall the driver's seat. Lay it back and reconnect to the center console. Be sure to line up the nuts with the marks from where they came off. Reconnect the electrical connectors. Reconnect the big connector, the base of the seat. Lay your seats back down.

Line them up with their bolt holes and the alignment mark, on the front inside mount on both sides. Start the bolts in the front of your seat, on both sides. Start the bolts in the rear. Using an 18 millimeter socket and ratchet, tighten down the rear bolts on the seat brackets. Torque the seat bolts to 30 foot-pounds.

Using the 15 millimeter socket and ratchet, tighten the front seat track bolts. Torque the front seat bolts to 34 pounds.

Reinstall the tab on the bottom of your seat belt into its hole. Over the stud, reinstall your bolt with a T-45 Torx socket. Torque the seat belt bolt to 29 foot-pounds. Repeat this step on the opposite side. Snap the plastic seat belt cover back into place.

Reinstall your negative battery terminal. Tighten it back with a 10 millimeter socket.

Thanks for tuning in. We hope this video helped you out. Next time you need parts for your car, please visit 1AAuto.com. Also check out our other helpful how-to and diagnosis videos.

Shop Products

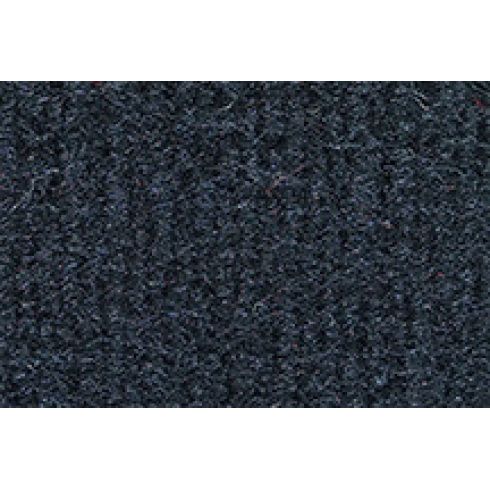

2003-08 Dodge Ram 1500 Truck Crew Cab Complete Carpet Auto Custom Carpets 16747-160-1116000000

Part Details:

- 840-Navy Blue

- Cutpile

- Molded

How to Replace Carpet 2000-05 Chevy Impala part 1

This video is part 1 of a 2 part video that shows how to open and prepare the new carpet, remove the seats and trim, and remove the old carpet for install